A Guide to Different Types of Cutters and Snips

When it comes to working with various materials, whether it's wire, metal, or plastic, having the right cutting tool or the best wire stripping tools is essential. Cutters and snips are designed to provide precise and clean cuts, making them indispensable in DIY projects, hardware shop retail, and global manufacturing.

In this comprehensive guide, we will explore different types of cutters and snips, their specific uses, and the factors to consider when choosing the right tool for your needs. From wire cutters to tin snips, this guide will help you understand the intricacies of each tool and ensure you have the right cutting instrument at your disposal.

Understanding Wire Cutters

Wire cutters are a versatile tool commonly used in electrical work, cable management, and various DIY projects. They are specifically designed to cut through different gauges of wire efficiently. Here are three main types of wire cutters:

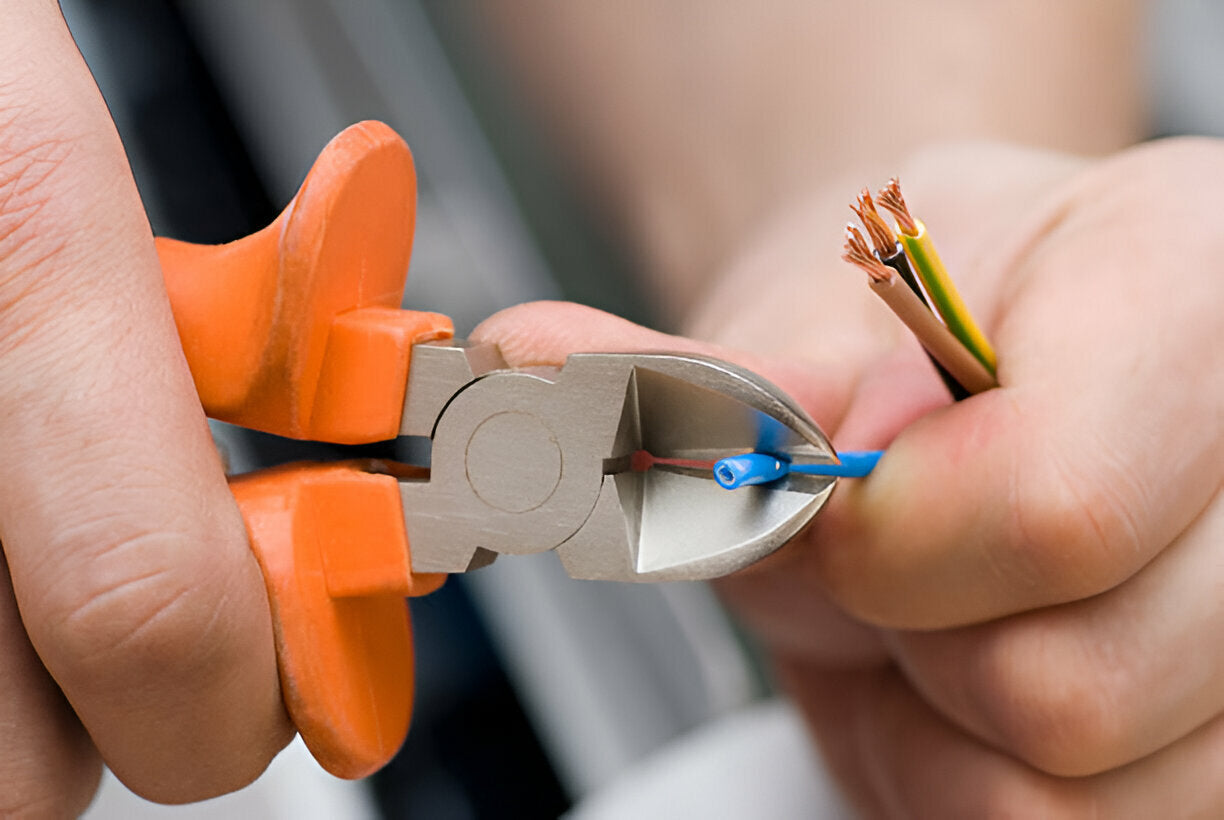

Diagonal Cutters

- Description: Diagonal cutters, also known as side cutters or diagonal pliers, have angled cutting edges that meet at a point. They are designed to cut wire close to the surface.

- Uses:

- Cutting through electrical wires, cables, and small nails.

- Trimming excess wire after stripping insulation.

- Precision cutting in tight spaces due to their compact size.

- Tips for Using Diagonal Cutters:

- Position the wire close to the base of the jaws.

- Squeeze the handles firmly to cut through the wire.

- Avoid twisting the tool while cutting to maintain clean and precise cuts.

Lineman's Pliers

- Description: Lineman's pliers, also known as combination pliers or side-cutting pliers, have a gripping area near the pivot and cutting edges closer to the tip. They are a multi-purpose tool that combines gripping and cutting functionalities.

- Uses:

- Cutting through larger wires, including copper and aluminum.

- Gripping, twisting, and bending wires.

- Pulling out nails or staples.

- Tips for Using Lineman's Pliers:

- Position the wire between the cutting edges, close to the pivot point.

- Apply steady pressure on the handles to cut through the wire.

- For thicker wires, use the leverage provided by the longer handles.

Wire Strippers

- Description: Wire strippers are specialized tools designed to remove the insulation from electrical wires without damaging the conductive wire itself. They have notched jaws or blades of various sizes to accommodate different wire gauges.

- Uses:

- Stripping insulation from electrical wires before making connections.

- Ensuring precise and consistent wire stripping.

- Navigating different wire gauges with adjustable stripping holes.

- Tips for Using Wire Strippers:

- Select the appropriate stripping hole size for the wire gauge.

- Insert the wire into the hole and squeeze the handles gently.

- Rotate the tool around the wire to score the insulation.

- Pull the wire and insulation apart to complete the stripping process.

Related Article: The Essential Guide to Wire Stripping Tools

Exploring Metal Cutting Tools

Metal cutting tools, such as snips, are essential for working with sheet metal, ductwork, and other metal materials. They come in different shapes and designs, each suited for specific cutting applications. Here are three common types of metal cutters:

Aviation Snips

- Description: Aviation snips, also known as compound snips or tin snips, are designed for cutting sheet metal. They have long handles and offset cutting jaws that allow easy cutting in tight curves and angles.

- Uses:

- Cutting and shaping sheet metal, including aluminum, steel, and copper.

- Navigating intricate curves and corners.

- Removing excess metal during fabrication or repairs.

- Tips for Using Aviation Snips:

- Position the metal between the cutting jaws, ensuring the desired cutting line aligns with the tool's blades.

- Squeeze the handles firmly to cut through the metal.

- For longer cuts, use a smooth and steady motion while applying even pressure.

Straight-Cut Snips

- Description: Straight-cut snips, also known as straight-pattern snips, are ideal for making long, straight cuts in sheet metal. They have straight blades and long handles that provide leverage for efficient cutting.

- Uses:

- Cutting straight lines in sheet metal.

- Trimming edges or removing excess metal.

- Creating precise cuts without distortion.

- Tips for Using Straight-Cut Snips:

- Position the snips at the desired starting point of the cut.

- Apply steady pressure on the handles while moving the tool along the cutting line.

- Use the full length of the blades to achieve cleaner and moreaccurate cuts.

Left-Cut and Right-Cut Snips

- Description: Left-cut and right-cut snips, also known as offset snips, are designed for cutting curves and circles in sheet metal. They have blades that are offset to the left or right, allowing greater visibility and maneuverability.

- Uses:

- Cutting curves and circles in sheet metal.

- Creating intricate shapes and designs.

- Working in confined spaces or tight angles.

- Tips for Using Left-Cut and Right-Cut Snips:

- Position the snips at the starting point of the curve or circle.

- Apply steady pressure on the handles while rotating the tool along the cutting line.

- Use short, controlled cuts for better precision and control.

Choosing the Right Cutter or Snip

When selecting a cutter or snip for your specific needs, there are a few factors to consider. Here are three essential considerations to help you make an informed decision:

Material Compatibility

Different cutters and snips are designed for specific materials. Ensure that the tool you choose is suitable for the material you will be working with. Consider the hardness, thickness, and composition of the material to determine the appropriate tool. For example:

- Wire cutters are designed to cut through various gauges of wire, including copper, aluminum, and steel.

- Metal snips are tailored for cutting sheet metal, such as aluminum, steel, and copper.

Cutting Capacity

Consider the maximum cutting capacity of the tool. This refers to the maximum thickness of the material the tool can handle. Ensure that the tool you choose can effectively cut through the material you will be working with. Using a tool with insufficient cutting capacity may result in uneven or incomplete cuts.

Ergonomics and Comfort

Since cutters and snips require manual force to operate, it's important to consider the ergonomics and comfort of the tool. Look for features such as cushioned handles, ergonomic grips, and smooth operation. A comfortable tool reduces fatigue and enhances precision during extended periods of use.

Related Article: From Wire to Wood: How to Use Snips for Clean Cuts

The Right Tool for Every Cut

In the world of DIY projects, hardware shop retail, and global manufacturing, having the right cutters and snips is essential for achieving clean, precise, and efficient cuts. Understanding the different types of wire cutters and metal snips, their specific uses, and the factors to consider when choosing the right tool will empower you to tackle various cutting tasks with confidence. Whether you're working with wires or sheet metal, selecting the appropriate cutting tool ensures optimal results and enhances your overall productivity. So, equip yourself with the right tools, and let your projects flourish with clean and accurate cuts!

Related Article: Safety Tips for Using Wire Stripping Tools