From Wire to Wood: How to Use Snips for Clean Cuts

From wire stripping to woodworking, the best snips and the best wire stripping tools are invaluable for achieving clean and precise cuts when working with different materials like wire and wood. Their versatility makes them essential for various DIY project's needs.

In this comprehensive guide, we will delve into the different types of snips available and explore effective techniques for their use. Whether you're looking to strip wires or make intricate cuts in wood, this guide will provide you with the necessary insights and tips to ensure clean and professional results in your projects.

Understanding Snips

Snips are cutting tools designed for a wide range of applications, including cutting wire, sheet metal, plastic, and even wood. They come in different shapes and sizes, each tailored to specific cutting tasks. Understanding the various types of snips is essential for selecting the right tool for the job. Here are three common types of snips:

Straight Snips

- Description: Straight snips, also known as straight-cut snips or aviation snips, have a straight and wide blade that cuts straight lines.

- Uses:

- Cutting sheet metal and plastic along straight lines.

- Trimming edges or removing excess material.

- Creating precise cuts without distortion.

- Tips for Using Straight Snips:

- Position the snips at the desired starting point of the cut.

- Apply steady pressure on the handles while moving the tool along the cutting line.

- Use the full length of the blades to achieve cleaner and more accurate cuts.

- Use a straightedge or ruler as a guide for longer cuts to ensure straight lines.

Left-Cut and Right-Cut Snips

- Description: Left-cut and right-cut snips, also known as offset snips, have blades that are offset to the left or right, respectively, allowing greater visibility and maneuverability when cutting curves and circles.

- Uses:

- Cutting curves and circles in sheet metal and plastic.

- Creating intricate shapes and designs.

- Working in confined spaces or tight angles.

- Tips for Using Left-Cut and Right-Cut Snips:

- Position the snips at the starting point of the curve or circle.

- Apply steady pressure on the handles while rotating the tool along the cutting line.

- Use short, controlled cuts for better precision and control.

- For smoother curves, make small adjustments and rotate the material as needed.

Multipurpose Snips

- Description: Multipurpose snips, also known as compound-action snips or combination snips, are versatile tools that can cut through various materials, including wire, sheet metal, and even wood.

- Uses:

- Cutting wires of different gauges.

- Trimming sheet metal, plastic, and wood.

- Navigating different cutting tasks with a single tool.

- Tips for Using Multipurpose Snips:

- Choose the appropriate snip blade or cutting edge for the material you're working with.

- Position the snips at the desired starting point of the cut.

- Apply steady pressure on the handles while moving the tool along the cutting line.

- For cutting wood, use a slow and controlled motion to prevent splintering.

Related Article: A Guide to Different Types of Cutters and Snips

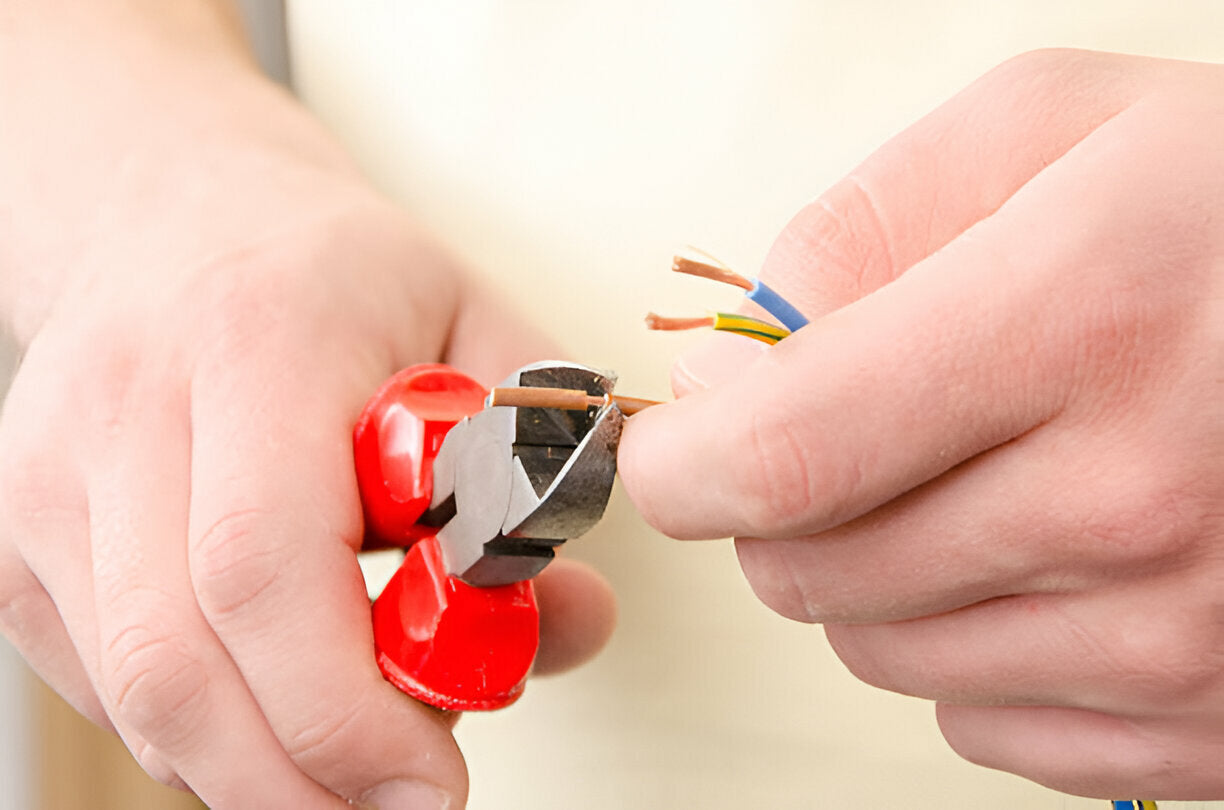

Using Snips for Wire Cutting

Snips are highly effective tools for cutting wires of various gauges. Whether you're working with electrical wires or conducting intricate wirework, using the right snips is crucial for clean and precise cuts. Here are three key techniques for using snips to cut wires:

Technique 1: Cutting Electrical Wires

- Description: When cutting electrical wires, it's essential to use snips specifically designed for wire cutting to ensure clean and safe cuts.

- Steps:

- Strip the wire's insulation using a wire stripper tool.

- Determine the desired length of the wire and mark it with a pen or marker.

- Position the wire between the cutting edges of the snips, close to the pivot point.

- Squeeze the handles firmly to cut through the wire.

- Inspect the cut end to ensure it is clean and free of burrs or frayed strands.

- If necessary, use a wire stripper tool to remove any remaining insulation from the cut end.

Technique 2: Cutting Thin Wires

- Description: When working with thin wires, such as jewelry wires or delicate electrical wires, precision is crucial to avoid damaging the wire.

- Steps:

- Determine the desired length of the wire and mark it with a pen or marker.

- Position the wire between the cutting edges of the snips, close to the pivot point.

- Apply gentle pressure on the handles to cut through the wire.

- Inspect thecut end to ensure a clean and smooth cut without any deformation or damage to the wire.

- If necessary, use a fine-grit sandpaper or file to smooth any rough edges on the cut end.

Technique 3: Cutting Heavy-Gauge Wires

- Description: Heavy-gauge wires, such as those used in construction or automotive applications, require snips with robust cutting capabilities.

- Steps:

- Determine the desired length of the wire and mark it with a pen or marker.

- Position the wire between the cutting edges of the heavy-duty snips, close to the pivot point.

- Apply strong and steady pressure on the handles to cut through the wire.

- Use both hands if necessary to ensure control and stability during the cutting process.

- Inspect the cut end to ensure a clean cut without any deformation or frayed strands.

Using Snips for Woodworking

While snips are primarily associated with cutting metal and wires, they can also be used for woodworking tasks that involve cutting thin wood pieces or trimming edges. Here are three techniques for using snips in woodworking:

Technique 1: Trimming Thin Wood Pieces

- Description: Snips can be used to trim small and thin wood pieces, such as dowels or trim strips, with precision and control.

- Steps:

- Place the wood piece on a stable surface or secure it in a vise.

- Position the snips above the area that needs to be trimmed.

- Apply steady pressure on the handles while cutting through the wood.

- Make controlled and small cuts to avoid splintering or damaging the wood.

- If necessary, use sandpaper or a file to smooth any rough edges left by the snips.

Technique 2: Cutting Veneer or Thin Plywood

- Description: Snips can be used to cut thin veneer or plywood sheets, providing a clean and straight cut without the need for power tools.

- Steps:

- Mark the desired cutting line on the veneer or plywood sheet using a straightedge or ruler.

- Position the snips at the starting point of the cut, aligning the cutting edges with the marked line.

- Apply steady pressure on the handles while moving the snips along the cutting line.

- Make sure to follow the marked line precisely to achieve a straight and clean cut.

- Inspect the cut edge to ensure it is smooth and free of splinters.

Technique 3: Trimming Wood Edges

- Description: Snips can be used to trim wood edges, such as those on laminate or veneered surfaces, providing a precise and clean cut.

- Steps:

- Mark the area that needs to be trimmed on the wood edge using a pencil or marker.

- Position the snips above the marked area, ensuring that the cutting edges are aligned with the line.

- Apply steady pressure on the handles while cutting through the wood edge.

- Make controlled and small cuts to avoid over-trimming or damaging the adjacent surface.

- Use sandpaper or a file to smooth the trimmed edge and achieve a clean finish.

Snips for Clean Cuts

Snips are versatile tools that find applications in various DIY projects, hardware shop retail, and global manufacturing. Whether you're working with wires or wood, understanding the different types of snips and their proper usage is key to achieving clean and precise cuts.

By following the techniques and tips outlined in this guide, you can leverage the power of snips to achieve professional results in your projects. Remember to select the appropriate snips for the task at hand, apply steady pressure, and make controlled cuts to ensure clean and accurate results. With snips in your toolbox, you'll be well-equipped to tackle a wide range of cutting needs, from wire stripping to woodworking.

Related Article: The Essential Guide to Wire Stripping Tools