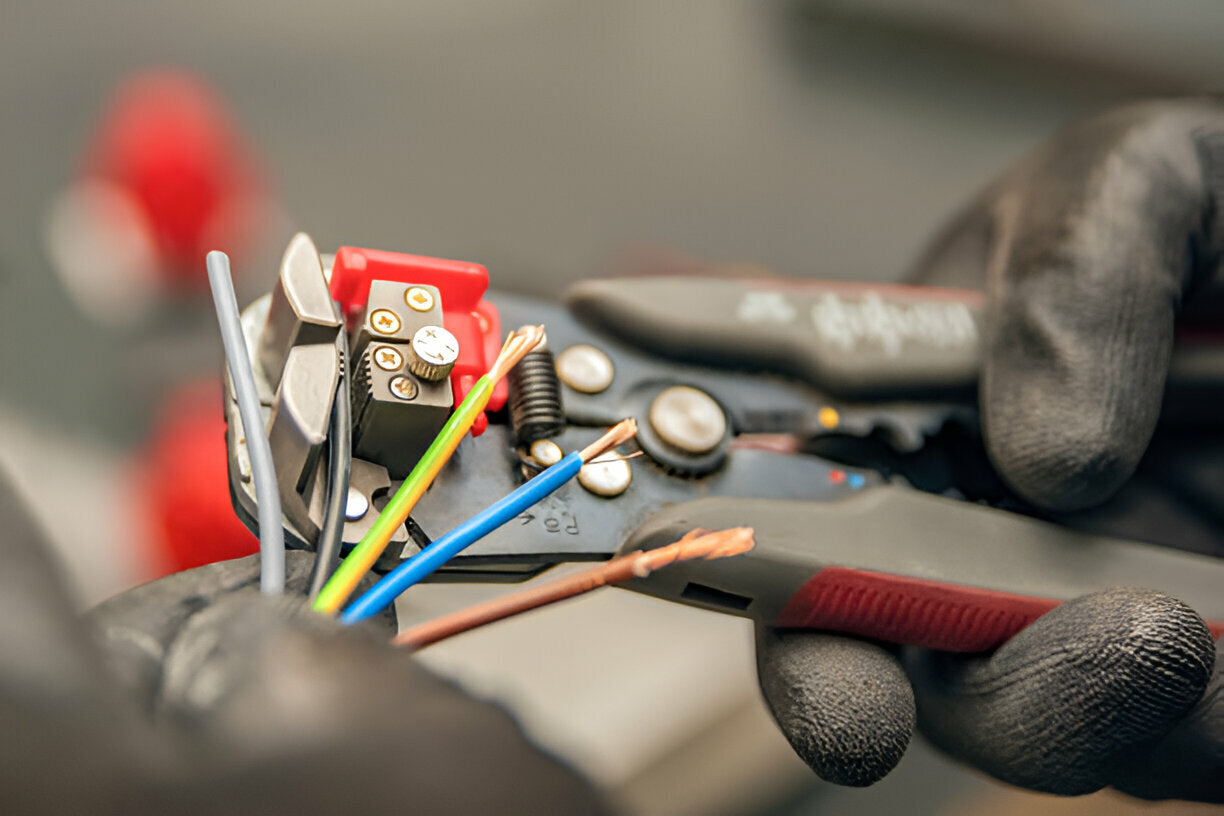

The Essential Guide to Wire Stripping Tools

Are you tired of struggling with outdated wire stripping tools that just don't get the job done efficiently? Look no further – in this comprehensive guide, we will explore everything you need to know about wire stripping tools. From understanding the basics of wire stripping to different types of tools available, we've got you covered. Whether you're a DIY enthusiast or a professional electrician, knowing how to choose, use, and maintain wire stripping tools is essential for any project. Let's dive in and discover the essential information you need to become a wire stripping pro.

Understanding Wire Stripping: The Basics

Wire stripping is a fundamental skill in electrical work that involves removing the insulation from electrical wires to expose the conductive metal underneath. This process is necessary for various applications, such as repairing electrical devices, installing new wiring systems, or creating connections between different components.

Why is Wire Stripping Important?

Wire stripping serves several purposes, including:

- Electrical Conductivity: The insulation on wires acts as a barrier, preventing the flow of electrical current. By removing the insulation, you expose the metal conductor, allowing for proper electrical conductivity.

- Connection and Termination: Stripped wires are essential for making secure and reliable connections. Whether you're splicing wires together, attaching connectors, or connecting to terminals, having properly stripped wires ensures a solid electrical connection.

- Troubleshooting and Repair: When dealing with faulty or damaged wires, stripping the insulation allows you to assess the condition of the wire and identify any issues that may be causing electrical problems.

Types of Wires

Before diving into wire stripping tools, it's important to understand the different types of wires commonly encountered in electrical work. Here are a few examples:

- Solid Wires: These wires consist of a single, solid conductor, typically made of copper or aluminum. They are commonly used in building wiring and electrical appliances.

- Stranded Wires: Composed of multiple smaller strands of wire, stranded wires offer greater flexibility and are more resistant to breakage. They are commonly used in applications where flexibility is required, such as automotive wiring or speaker cables.

- Multiconductor Cables: These cables contain multiple wires within a single sheath. They are often found in data communication systems, audio/video cables, or power cords.

Understanding the type of wire you are working with is crucial, as it may influence the choice of wire stripping tool and technique you use.

Wire Gauge

Wire gauge refers to the size of the wire, specifically the diameter or cross-sectional area. It is an important factor to consider when selecting a wire stripping tool, as different gauges require different stripping capabilities. Common wire gauge measurements include American Wire Gauge (AWG) or metric measurements like millimeters squared (mm²).

To ensure efficient wire stripping, it is essential to choose a tool that accommodates the wire gauge you are working with. Using an inappropriate tool can lead to damaged wires or inconsistent stripping results.

Safety Precautions

Working with electrical wires involves inherent risks. To ensure your safety and the safety of others, it is crucial to follow proper safety precautions when using wire stripping tools. Some important safety measures include:

- Disconnect Power: Before working with any wires, make sure to turn off the power source and disconnect it from the circuit.

- Wear Protective Gear: Use appropriate personal protective equipment (PPE) such as safety glasses, gloves, and insulated footwear to protect against potential electrical shocks or injuries.

- Inspect Wires: Before stripping, inspect the wires for any signs of damage, fraying, or exposed conductors. Damaged wires should be replaced rather than stripped.

- Proper Tool Handling: Handle wire stripping tools with care, ensuring that you grasp them firmly and use them in a controlled manner. Avoid applying excessive force that could damage the wire or the tool.

By following these basic guidelines, you can minimize the risks associated with wire stripping and ensure a safe working environment. Now that we have covered the basics of wire stripping, let's move on to exploring the different types of wire stripping tools available.

Related Article: Safety Tips for Using Wire Stripping Tools

Types of Wire Stripping Tools

Wire stripping tools come in various types, each designed to cater to different needs and preferences. Understanding the different types will help you choose the right tool for your specific wire stripping requirements. Let's explore the three main categories of wire stripping tools:

1. Manual Wire Strippers

Manual wire strippers are handheld tools that require manual force to strip the wire. They are simple and easy to use, making them a popular choice for DIY enthusiasts and professionals alike. Here are some common types of manual wire strippers:

- Standard Wire Strippers: These are basic wire stripping tools with a pair of opposing blades that cut through the insulation while leaving the conductor intact. They often have adjustable settings to accommodate different wire gauges.

- Precision Wire Strippers: Precision wire strippers are designed for delicate and precise wire stripping tasks. They typically feature adjustable blades or notches to ensure precise cutting depths, making them suitable for working with small-gauge wires.

- Self-Adjusting Wire Strippers: These wire strippers automatically adjust their cutting depth based on the wire gauge, eliminating the need for manual adjustments. They are convenient for stripping a wide range of wire sizes quickly and accurately.

2. Automatic Wire Strippers

Automatic wire strippers are powered tools that automate the wire stripping process, reducing the effort required. They are commonly used in professional settings where large volumes of wires need to be stripped efficiently. Here are a few types of automatic wire strippers:

- Electric Wire Strippers: Electric wire strippers use an electric motor to rotate the wire against a cutting blade, removing the insulation. They often have adjustable settings, allowing for precise stripping and faster operation.

- Pneumatic Wire Strippers: Pneumatic wire strippers utilize compressed air to power the stripping mechanism. They are ideal for heavy-duty stripping tasks and can handle a wide range of wire sizes.

3. Infrared and Laser Wire Strippers

Infrared and laser wire strippers are advanced tools that use heat to remove insulation without physical contact. They are typically used in specialized industries where precision and non-contact stripping are crucial. Here are the two main types:

- Infrared Wire Strippers: Infrared wire strippers use infrared radiation to heat the insulation, causing it to melt or become brittle. The insulation can then be easily removed without damaging the conductor. These tools are commonly used for delicate wires or heat-sensitive materials.

- Laser Wire Strippers: Laser wire strippers utilize a laser beam to selectively remove the insulation layer. The laser energy vaporizes or ablates the insulation, leaving the conductor intact. Laser wire strippers offer high precision and are often used in industries like aerospace or medical device manufacturing.

Each type of wire stripping tool has its advantages and limitations. Consider factors such as the volume of wires you will be working with, the wire gauge range, and the level of precision required to determine the most suitable type for your needs. In the next section, we will delve into the proper usage of wire stripping tools to ensure efficient and accurate results.

Related Article: A Guide to Different Types of Cutters and Snips

How to Use Wire Stripping Tools

Using wire stripping tools correctly is essential to achieve efficient and accurate results while ensuring your safety. Whether you are working with manual, automatic, or specialized wire stripping tools, the following guidelines will help you use them effectively:

1. Proper Safety Measures

Before using any wire stripping tool, make sure to take the necessary safety precautions:

- Power Off: Ensure that the power source is turned off and disconnected before handling any wires. This prevents the risk of electrical shock or short circuits.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and insulated footwear, to protect yourself from potential hazards.

2. Using Manual Wire Strippers

To use manual wire strippers:

- Select the Correct Gauge Setting: Adjust the tool's cutting jaws or settings to match the wire gauge you are working with. This ensures that the blades make proper contact with the insulation without damaging the conductor.

- Position the Wire: Hold the wire firmly and insert it into the stripping area of the tool. The insulation should be positioned between the cutting blades.

- Apply Pressure and Rotate: Apply even pressure to the handles of the wire stripper while rotating it around the wire. This allows the cutting blades to score and cut through the insulation.

- Remove the Insulation: Once the insulation is cut, gently pull the wire stripper away from the wire, removing the insulation along with it. Be careful not to pull too hard, as this may damage the conductor.

3. Using Automatic Wire Strippers

When using automatic wire strippers:

- Adjust the Settings: Set the tool's cutting depth or wire gauge adjustment to match the wire you are working with. This ensures that the tool removes the insulation without damaging the conductor.

- Position the Wire: Insert the wire into the stripping area of the tool, ensuring that the insulation is properly aligned with the cutting mechanism.

- Activate the Tool: Depending on the type of automatic wire stripper, activate the tool by pressing a button or engaging the power switch. The tool will automatically strip the wire by rotating the cutting mechanism against the insulation.

- Remove the Insulation: Once the stripping process is complete, gently pull the wire away from the tool, removing the stripped insulation. Take care not to damage the conductor during this step.

4. Using Infrared and Laser Wire Strippers

Using infrared or laser wire strippers requires specialized knowledge and equipment. It is crucial to follow the manufacturer's instructions and safety guidelines provided with the specific tool you are using. Here are some general steps:

- Prepare the Wire: Ensure that the wire is clean and free from any contaminants or debris that may interfere with the stripping process.

- Position the Tool: Set up the infrared or laser wire stripper according to the manufacturer's instructions, ensuring that the wire is properly aligned with the tool.

- Activate the Tool: Activate the tool's heat source (infrared or laser) following the provided instructions. The heat will melt or ablate the insulation, allowing it to be easily removed.

- Remove the Insulation: Once the insulation is heated, gently pull or wipe it away from the wire. Take care to avoid touching the hot or melted insulation to prevent burns.

Related Article: From Wire to Wood: How to Use Snips for Clean Cuts

Maintenance and Care for Your Wire Stripping Tools

Proper maintenance and care are crucial for ensuring the longevity and optimal performance of your wire stripping tools. By following these maintenance tips, you can keep your tools in excellent condition and maximize their effectiveness:

1. Cleaning Your Wire Strippers

Regular cleaning helps remove dirt, debris, and residue that can accumulate on your wire stripping tools. Here's how to clean them effectively:

- Inspect the Tool: Before cleaning, inspect the tool for any signs of damage or wear. If you notice any issues, address them before proceeding with the cleaning process.

- Remove Residue: Use a soft brush or cloth to gently remove any dirt, dust, or residue from the tool's blades, handles, and cutting mechanisms. Avoid using abrasive materials that could scratch or damage the tool's surfaces.

- Use a Cleaning Solution: For stubborn residue or grease, you can use a mild cleaning solution or degreaser. Apply the solution to a cloth and carefully clean the affected areas. Ensure that the tool is completely dry before using it again.

2. Sharpening the Blades

Over time, the cutting blades of wire stripping tools can become dull, affecting their performance. Sharpening the blades helps maintain their effectiveness. Here's how to sharpen the blades:

- Inspect the Blades: Examine the cutting blades for any signs of dullness, nicks, or damage. If the blades are severely damaged, consider replacing them instead of sharpening.

- Choose the Right Sharpening Method: Depending on the type of wire stripping tool and its blades, you can use various sharpening methods, such as using a sharpening stone, a file, or a specialized sharpening tool. Refer to the manufacturer's instructions for the recommended sharpening method.

- Follow the Sharpening Technique: Carefully follow the appropriate sharpening technique for your specific tool. This may involve gently moving the blade against the sharpening surface in a specific motion or angle. Take your time and ensure that you maintain the proper blade shape and edge.

- Test the Blades: After sharpening, test the blades by using the tool on a scrap wire. If the blades cut smoothly and cleanly, without damaging the conductor, then the sharpening process was successful.

3. Proper Storage

Storing your wire stripping tools correctly helps protect them from damage and ensures they are readily accessible when needed. Consider the following storage tips:

- Clean and Dry: Before storing your tools, make sure they are clean and dry to prevent corrosion or damage.

- Separate and Organize: Store your wire stripping tools separately from other tools to avoid potential damage or entanglement. Use toolboxes, tool racks, or designated compartments to keep them organized and easily accessible.

- Protective Covers or Sheaths: Consider using protective covers or sheaths to prevent the blades of your wire stripping tools from getting damaged or causing accidental injuries.

- Avoid Extreme Temperatures and Humidity: Store your tools in a cool, dry place away from direct sunlight, extreme temperatures, or high humidity. These conditions can accelerate corrosion or cause damage to the tool's components.

4. Regular Inspection for Wear and Tear

Regularly inspecting your wire stripping tools helps identify any signs of wear, damage, or malfunction. Here's what to look for during inspections:

- Blade Condition: Check the cutting blades for any signs of dullness, chipping, or misalignment. If the blades are damaged or worn, consider replacing them to ensure optimal performance.

- Handle Condition: Inspect the handles for any cracks, loose parts, or signs of wear. Damaged handles could compromise the tool's stability and usability.

- Mechanism Functionality: Test the stripping mechanism to ensure it operates smoothly and without any sticking or jamming. If you notice any issues, address them promptly.

By following these maintenance and care tips, you can prolong the lifespan of your wire stripping tools and ensure they remain in excellent working condition. Now that you know how to maintain your tools, let's move on to the next section, where we will guide you through the process of selecting the right wire stripping tool for your needs.

Buying Guide: Choosing the Right Wire Stripping Tool

Choosing the right wire stripping tool is essential to ensure efficient and accurate wire stripping for your specific needs. With various options available in the market, it's important to consider certain factors before making a purchase. Here's a comprehensive buying guide to help you choose the perfect wire stripping tool:

1. Consider Your Usage Needs

First, determine the specific tasks and projects you will be using the wire stripping tool for. Consider factors such as the wire gauge range you will be working with, the volume of wires you will be stripping, and the level of precision required. This will help you narrow down the options and choose a tool that meets your specific usage needs.

2. Budget and Quality

Set a budget for your wire stripping tool purchase, but also prioritize quality. While it can be tempting to opt for cheaper options, investing in a high-quality tool will save you money in the long run. Look for tools made from durable materials and with solid construction to ensure longevity and reliable performance.

3. Brand and Customer Reviews

Research reputable brands known for manufacturing reliable and high-quality wire stripping tools. Check customer reviews and ratings to get insights into the experiences of other users. Pay attention to feedback regarding durability, ease of use, and accuracy of the stripping process.

4. Ergonomics and Comfort

Consider the ergonomics and comfort features of the wire stripping tool. Look for tools with comfortable handles and a design that allows for easy grip and control. Ergonomic features such as cushioned grips or anti-slip materials can reduce strain and fatigue during prolonged use.

5. Stripping Capability and Versatility

Ensure that the wire stripping tool you choose can handle the wire gauge range you typically work with. Check for adjustable settings or interchangeable blades to accommodate different wire sizes. Additionally, consider if the tool offers additional features or attachments that can expand its versatility, such as the ability to crimp or cut wires.

6. Safety Features

Pay attention to the safety features offered by the wire stripping tool. Look for tools that have insulation barriers to prevent accidental contact with live conductors, as well as features that minimize the risk of cuts or injuries during the stripping process. Safety features like spring-loaded handles or locking mechanisms can enhance user safety.

7. Warranty and Customer Support

Check if the wire stripping tool comes with a warranty. A reliable warranty shows the manufacturer's confidence in their product's quality. Additionally, consider the availability of customer support, as it can be helpful in case you encounter any issues or have questions about the tool.

8. Try Before You Buy

If possible, try out the wire stripping tool before making a purchase. Visit a local hardware store or attend trade shows where you can test different models and get a feel for their performance, comfort, and functionality. This hands-on experience can help you make a more informed decision.

By considering these factors and conducting thorough research, you can select a wire stripping tool that meets your specific requirements and offers long-lasting performance. Remember, choosing the right tool will enhance your productivity, accuracy, and overall satisfaction with your wire stripping tasks.

Now that you have a comprehensive understanding of wire stripping tools, their types, usage, maintenance, and selection, you are well-equipped to tackle any wire stripping project with confidence. Happy wire stripping!