Magnetic vs. Non-Magnetic Tools: Which Are Better for Computer Repair?

When it comes to fixing computers, the tools available in your computer repair tool kit can really make a significant difference in the overall efficiency and effectiveness of your repair work. There are two main types of tools that you should be aware of: magnetic and non-magnetic tools. Each type has its own unique benefits and drawbacks that can impact your repair experience.

This article will help you understand these tools in greater detail and guide you in making informed decisions about which ones are best suited for your specific repair needs.

Key Takeaways

-

Magnetic tools help keep screws from falling, making them easier to use in tight spots.

-

Non-magnetic tools avoid any risk of interfering with computer parts, ensuring precision.

-

Choosing the right tool depends on the job at hand, balancing safety and effectiveness.

Understanding Magnetic and Non-Magnetic Tools

Definition and Types of Magnetic Tools

Magnetic tools are ingeniously designed with powerful magnets that effectively help hold screws and small metal parts securely in place. These specialized tools are particularly useful in tight spaces where dropping a screw can be a significant hassle, leading to time-consuming searches and potential frustration. These include:

-

Magnetic screwdrivers

-

Magnetic trays

-

Magnetic pick-up tools

Definition and Types of Non-Magnetic Tools

Non-magnetic tools do not possess any magnetic properties and are constructed from a variety of materials such as plastic, wood, or specific types of metals that are inherently non-magnetic.

These tools are absolutely essential for a wide range of tasks where the presence of magnetism could potentially cause significant issues or complications, such as:

-

Precision screwdrivers

-

Plastic prying tools

-

Non-magnetic tweezers

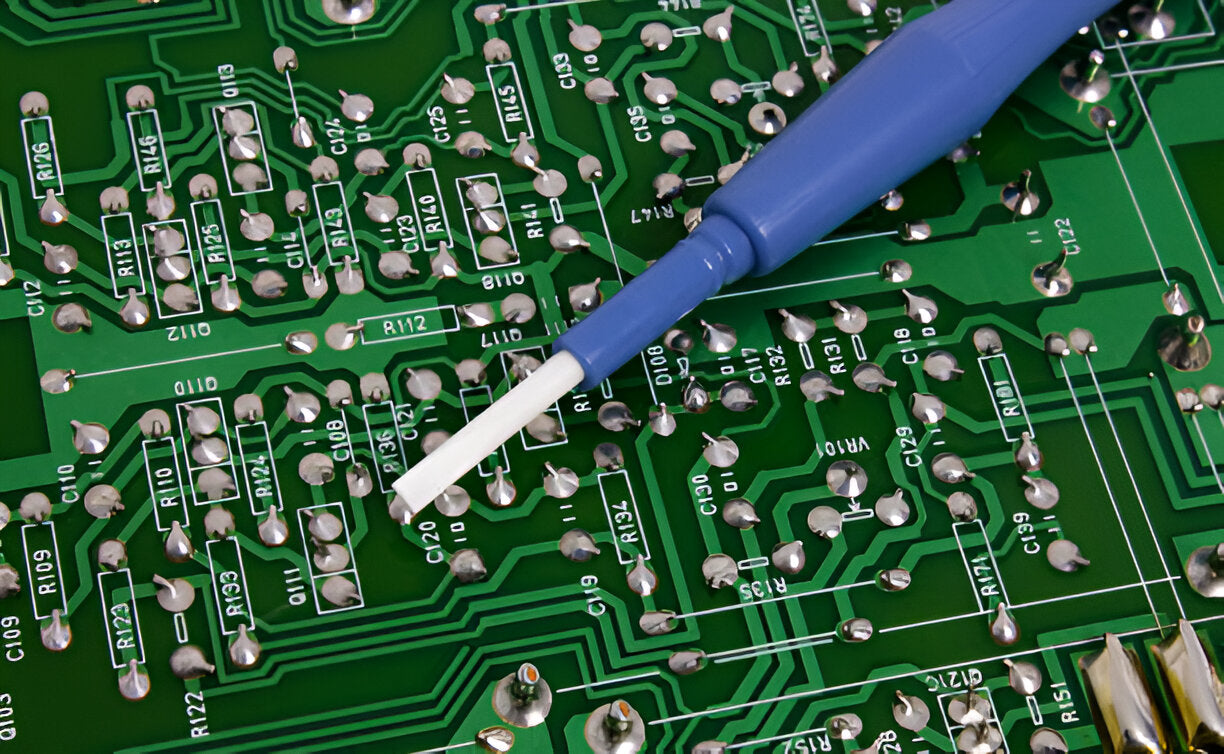

Common Uses in Computer Repair

Both magnetic and non-magnetic tools have their place in computer repair. Here are some common uses:

-

Magnetic tools help in holding screws securely, making it easier to work in cramped areas.

-

Non-magnetic tools are crucial when working near sensitive components to avoid any risk of interference.

|

Tool Type |

Common Uses |

|---|---|

|

Magnetic Tools |

Holding screws, organizing parts |

|

Non-Magnetic Tools |

Precision work, avoiding interference |

In computer repair, the choice between magnetic and non-magnetic tools often depends on the specific task at hand. Understanding their properties can lead to more efficient repairs.

Advantages of Using Magnetic Tools in Computer Repair

Preventing Screw Loss

Magnetic tools, especially screwdrivers, are designed to hold screws securely. This feature is particularly beneficial in computer repair, where small screws can easily be lost. Using a magnetic screwdriver helps keep screws in place, reducing the risk of losing them during repairs.

Ease of Use in Tight Spaces

When working inside a computer case, space can be limited. Magnetic tools allow for easier maneuvering in these tight areas. They can hold screws in position, making it simpler to insert or remove them without dropping them into hard-to-reach spots.

Safety Considerations

Using magnetic tools can enhance safety during repairs. They minimize the chances of dropping screws onto sensitive components, which could cause damage. Additionally, magnetic screwdrivers are safer to handle than traditional ones, as they reduce the risk of sharp edges causing injuries.

Magnetic tools are not only practical but also contribute to a safer and more efficient repair process.

Summary of Advantages

|

Advantage |

Description |

|---|---|

|

Prevents screw loss |

Holds screws securely, reducing the chance of losing them. |

|

Simplifies tight space work |

Easier to maneuver in confined areas without dropping screws. |

|

Enhances safety |

Reduces the risk of injury and damage to components during repairs. |

Advantages of Using Non-Magnetic Tools in Computer Repair

Avoiding Potential Magnetic Interference

Non-magnetic tools are essential in computer repair, especially when working with sensitive components. Using non-magnetic tools helps prevent any risk of magnetic interference that could potentially disrupt the functioning of hard drives and other electronic parts. This is particularly important for older devices that may still be sensitive to magnetic fields.

Precision and Control

Non-magnetic tools offer a level of precision that is crucial in computer repair. Here are some benefits:

-

Enhanced control: Non-magnetic tools allow for better handling, especially in tight spaces.

-

Reduced risk of damage: They minimize the chance of scratching or damaging delicate components.

-

Accurate torque application: Non-magnetic screwdrivers can provide a more consistent torque, which is vital for securing screws without over-tightening.

Durability and Material Strength

Non-magnetic tools are often made from high-quality materials that enhance their durability. Some advantages include:

-

Longer lifespan: Non-magnetic tools tend to resist wear and tear better than their magnetic counterparts.

-

Corrosion resistance: Many non-magnetic tools are made from stainless steel or other materials that resist rust and corrosion.

-

Versatility: They can be used in various applications beyond computer repair, making them a valuable addition to any toolkit.

In summary, while magnetic tools have their advantages, non-magnetic tools provide essential benefits that enhance safety, precision, and durability in computer repair.

Choosing the Right Tool for Your Computer Repair Tool Kit

Assessing the Task Requirements

When selecting tools for computer repair, it is crucial to evaluate the specific tasks you will be performing. Consider the following:

-

Type of components: Are you working with delicate parts or robust hardware?

-

Screw types: Do you need Phillips, flathead, or specialty screws?

-

Space constraints: Will you be working in tight areas?

Balancing Safety and Efficiency

Choosing the right tools also involves balancing safety and efficiency. Here are some points to consider:

-

Magnetic tools can help prevent screw loss but may pose risks to sensitive components.

-

Non-magnetic tools offer precision and control, especially in delicate situations.

-

Durability: Ensure your tools can withstand repeated use without breaking.

Recommendations for Essential Tools

To build a reliable computer repair toolkit, consider including the following essential tools:

-

Magnetic screwdrivers for easy screw handling.

-

Precision tweezers for picking up small components.

-

Anti-static wrist straps to prevent static damage.

A well-rounded toolkit not only enhances your efficiency but also ensures the safety of your computer components.

Related Article: Pro Tips for Using Screwdrivers on Computer, Laptops & More

Using Magnetic Tools in Computer Repair

In summary, magnetic screwdrivers are practical tools for computer repair. They help keep screws in place, making it easier to work without losing them. While some people worry about using magnets near computers, modern devices are designed to handle them safely. So, if you're fixing a computer, using a magnetic screwdriver can be a smart choice. Just remember to be careful and follow good practices to avoid any issues.

Related Article: Computer Tool Kit Guide: Everything You Need to Know