Soldering vs. Desoldering: Techniques and Best Practice

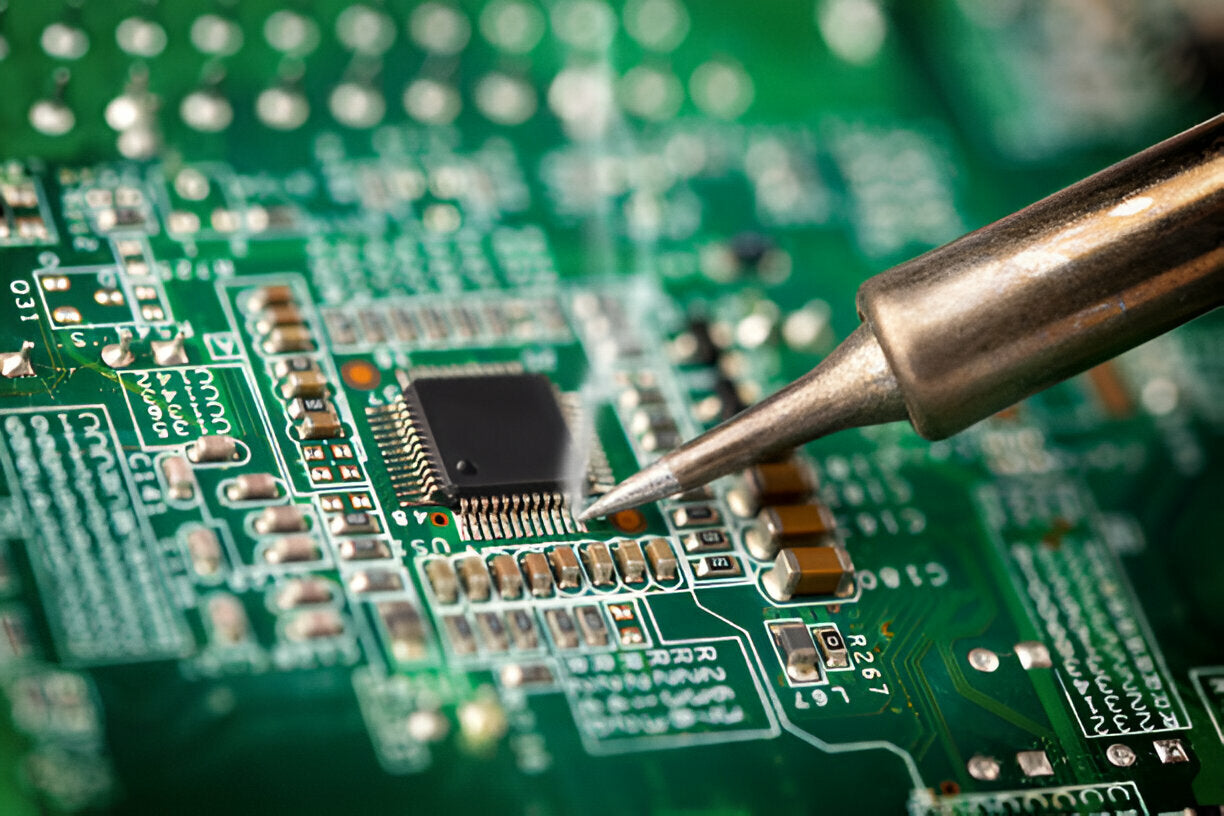

When it comes to working with electronic components, soldering and desoldering are two essential techniques that every DIY enthusiast and hardware shop retailer should be familiar with. Soldering involves joining components together using molten solder, while desoldering is the process of removing soldered connections.

In this article, we will explore the techniques and best practices for both soldering and desoldering. Whether you're a beginner or an experienced professional, understanding these techniques and following the right practices will help you achieve reliable and high-quality results. Additionally, we will discuss the importance of soldering accessories for electronics in ensuring successful soldering and desoldering processes.

Soldering: The Basics and Beyond

Soldering is a fundamental technique used in various electronic projects and repairs. It involves melting a filler metal, known as solder, to create a permanent bond between two or more components. Let's start by understanding the basics of soldering.

Soldering Tools and Equipment

Before you begin soldering, it's crucial to have the right tools and equipment at hand:

- Soldering Iron: A soldering iron is the primary tool used for melting solder. Choose a soldering iron with an appropriate wattage for your project.

- Solder: Select a solder with the right composition for your application. Common types include lead-based solder (with or without silver) and lead-free solder.

- Flux: Flux is a chemical agent that helps clean the surfaces to be soldered and promotes better wetting and adhesion of the solder. Choose a flux suitable for your soldering materials.

- Soldering Stand: A soldering stand provides a safe place to rest the soldering iron when not in use. It helps prevent accidental burns and protects your work surface.

- Soldering Accessories: Additional accessories like soldering tips, soldering wick, and helping hands can enhance your soldering experience and improve precision.

Related Article: Types of Soldering Irons and Their Uses

Soldering Techniques

To achieve successful soldering, follow these key techniques:

- Prepare the Components: Ensure the components to be soldered are clean and free from dirt, oxidation, or any other contaminants. Use isopropyl alcohol or a specialized cleaning agent to remove any residue.

- Tinning the Soldering Iron Tip: Before starting, tin the soldering iron tip by applying a small amount of solder to it. This helps improve heat transfer and prevents oxidation.

- Heat Control: Heat the components to be soldered, not the solder itself. Apply the soldering iron tip to the joint and allow it to heat the components evenly.

- Solder Application: Once the components reach the desired temperature, touch the solder to the joint, not the soldering iron tip. Allow the solder to flow and create a smooth, shiny connection.

- Avoid Excessive Solder: Use only the necessary amount of solder to create a strong and reliable joint. Excessive solder can lead to bridging and poor electrical connections.

Common Soldering Mistakes to Avoid

While soldering, it's essential to be aware of common mistakes that can compromise the quality of your solder joints. Avoid the following:

- Cold Joints: Insufficient heating or premature movement can result in cold joints, which have poor electrical conductivity and mechanical strength.

- Solder Bridges: Excessive solder can create unintentional connections between adjacent pins or pads, causing short circuits.

- Overheating: Excessive heat can damage sensitive components, melt plastic parts, or lift circuit board traces.

- Insufficient Flux: Inadequate flux application can lead to poor wetting and weak solder joints.

Desoldering: Removing Soldered Connections

Desoldering is the process of removing soldered connections for repairs, modifications, or component replacement. It allows for the removal of faulty components or the correction of soldering errors. Let's explore the techniques and best practices for effective desoldering.

Desoldering Tools and Equipment

To desolder effectively, you will need the following tools:

- Desoldering Pump: A desoldering pump, also known as a solder sucker, is a manual tool that creates suction to remove molten solder from joints.

- Desoldering Braid: Desoldering braid, also called solder wick, is a braided copper wire used to wick away molten solder from connections.

- Desoldering Station: A desoldering station combines a soldering iron with a built-in vacuum pump to provide precise temperature control and automated suction for desoldering.

Desoldering Techniques

Follow these techniques to desolder components effectively:

Desoldering Pump Method

- Heat the soldered joint with a soldering iron to melt the solder.

- Position the desoldering pump near the molten solder and press the plunger to create suction.

- As the molten solder is sucked into the desoldering pump, remove the pump and release the plunger to expel the solder into a waste container.

Desoldering Braid Method

- Heat the soldered joint with a soldering iron to melt the solder.

- Place the desoldering braid directly on the molten solder and press it against the joint.

- The desoldering braid will absorb the molten solder through capillary action. Move the braid along the joint to remove the solder effectively.

- Once the braid has absorbed the solder, remove it from the joint and trim off the used portion.

Desoldering Station Method

- Set the temperature of the desoldering station to the appropriate level for the solder being used.

- Position the desoldering nozzle around the soldered joint and activate the vacuum pump.

- The nozzle will heat the solder and simultaneously create suction to remove the molten solder.

- Move the nozzle along the joint to remove all the solder effectively.

Best Practices for Desoldering

To ensure successful desoldering, consider the following best practices:

- Heat Control: Apply heat only to the joint you want to desolder to minimize the risk of damaging nearby components or the circuit board.

- Avoid Excessive Heat: Excessive heat can damage components or lift circuit board traces. Use the lowest temperature required to melt the solder effectively.

- Clean the Tip: Regularly clean the desoldering tool's tip to remove any accumulated solder or debris, as it can hinder the suction or wicking action.

- Practice Patience: Allow the solder to fully melt before attempting to remove it. Rushing the process may result in incomplete desoldering or damage to the components.

Importance of Soldering Accessories for Electronics

Soldering accessories play a crucial role in ensuring successful soldering and desoldering processes. Here are some essential accessories and their importance:

Soldering Tips

- Different soldering tips are available for various applications, such as fine point tips for precision work or chisel tips for broader connections.

- Proper tip selection ensures efficient heat transfer and precise solder flow, resulting in reliable and professional-quality joints.

Soldering Wick

- Soldering wick, also known as desoldering braid, is a useful accessory for removing excess solder or correcting soldering mistakes.

- It absorbs molten solder through capillary action and helps create clean and well-defined joints.

Helping Hands

- Helping hands are adjustable tools that hold components or wires in place during soldering, providing stability and freeing up your hands for precise soldering.

- They are especially useful when working with small or delicate components that require steady positioning.

Flux

- Flux is essential for proper wetting and adhesion of the solder to the components being soldered.

- It helps remove oxidation, dirt, and other contaminants from the surfaces, promoting better solder flow and reliable connections.

Soldering Iron Stand

- A soldering iron stand provides a secure and stable place to rest the soldering iron when not in use, preventing accidental burns or damage to your work surface.

- It also ensures that the soldering iron is safely stored and easily accessible during soldering sessions.

Proper utilization of these soldering accessories enhances the overall soldering experience and improves the quality and reliability of the solder joints.

Achieving Excellence in Soldering and Desoldering

Mastering the techniques and best practices of soldering and desoldering is essential for DIY enthusiasts, hardware shop retailers, and professionals working with electronic components. By following the right procedures, using appropriate tools and equipment, and incorporating soldering accessories, you can achieve excellent results in your projects and repairs.

Related Article: Choosing the Right Soldering Iron: A Buyer's Guide