A Guide to Soldering Tool Accessories

Soldering is a fundamental skill in electronics and DIY projects, and having the right tools and accessories is crucial for successful soldering. Whether you're a beginner or a seasoned pro, understanding the different soldering tool accessories available can enhance your soldering experience and improve the quality of your work.

In this comprehensive guide, we'll explore the various types of soldering tools and accessories, how to use them effectively, and essential maintenance tips to keep your tools in top condition. By the end of this post, you'll be equipped with the knowledge to choose the right soldering tools for your projects and solder like a pro.

Understanding Soldering Basics

Soldering is a process of joining two or more metal components using a filler metal called solder. Before diving into the world of soldering tool accessories, it's essential to have a solid understanding of the basics of soldering. This section will cover the fundamental principles and concepts that form the foundation of soldering techniques.

What is Solder?

To comprehend soldering, it's crucial to understand what solder is and how it works. Solder is a metal alloy with a low melting point that is used to create a bond between two metal surfaces. It is typically composed of a combination of tin and lead, although lead-free solder options are also available. Solder is available in various forms, such as wire, paste, or pre-cut pieces, and it comes in different compositions and sizes to suit different applications.

Related Article: Types of Soldering Irons and Their Uses

Soldering Process

Soldering involves the application of heat to melt the solder, which then flows and forms a solid connection between the metal components. The process requires a soldering iron or a soldering station, which provides the necessary heat to melt the solder. The molten solder then creates a metallurgical bond with the metal surfaces, creating a strong and durable joint.

Types of Soldering Joints

There are several types of soldering joints that are commonly used in various projects. Understanding the different joint types can help you determine the appropriate soldering technique and tool accessories needed for specific applications. Some common soldering joint types include:

- Lap Joint: In this joint, the two metal surfaces are overlapped and soldered together along the seam.

- Through-Hole Joint: This joint involves inserting a component lead through a hole on a circuit board and soldering it from the other side.

- Surface Mount Joint: Surface mount technology (SMT) involves soldering components directly onto the surface of a circuit board, creating small, flat joints.

- T-Joint: In a T-joint, one component is soldered perpendicularly to another, forming a T-shape.

Soldering Equipment

Apart from solder, the primary tool required for soldering is a soldering iron. A soldering iron is a handheld device that generates heat to melt the solder. There are various types of soldering irons available, including pencil irons, temperature-controlled irons, and cordless irons. Each type has its advantages and is suitable for different soldering applications.

To ensure safe and efficient soldering, other essential equipment includes:

- Soldering station: A soldering station combines a soldering iron with a temperature control unit, allowing precise temperature regulation.

- Soldering stand: A stand provides a safe place to rest the soldering iron when not in use, reducing the risk of accidental burns or damage.

- Soldering tip cleaner: Cleaning the soldering iron tip helps remove oxidation and keeps it in optimal condition.

Understanding the basics of soldering is crucial before delving into the world of soldering tool accessories. With a solid foundation in soldering principles, you'll be well-prepared to explore the different types of soldering tool accessories and their applications.

Types of Soldering Tool Accessories

Soldering tool accessories are essential components that complement soldering irons and aid in achieving precise and efficient soldering results. In this section, we will explore the different types of soldering tool accessories available in the market and their specific purposes. Understanding these accessories will enable you to choose the right tools for your soldering projects.

Different Types of Solder

Before diving into soldering tool accessories, it's crucial to understand the various types of solder available. Different solder compositions have distinct melting points, flow characteristics, and applications. The most common solder types include:

- Lead-Tin Solder: This traditional solder contains a combination of lead and tin. It has excellent wetting properties and is commonly used in electronics and plumbing applications. However, due to environmental concerns, lead-free solder options are gaining popularity.

- Lead-Free Solder: As the name suggests, lead-free solder is free from lead and is composed of alternative alloys such as tin, silver, and copper. It meets environmental regulations and is commonly used in electronic applications.

- Flux-Core Solder: Flux-core solder incorporates a flux core within the solder wire. Flux is a chemical compound that aids in removing oxidation and promoting solder flow. Flux-core solder eliminates the need for applying separate flux during soldering.

Soldering Irons and Their Varieties

Soldering irons are the primary tools used in soldering, and they come in various types and models. Understanding the different soldering iron varieties will help you choose the most suitable one for your specific soldering needs. Some common types of soldering irons include:

- Pencil Soldering Iron: Pencil soldering irons are lightweight and compact, making them ideal for intricate soldering tasks. They are available in different wattages and offer precise control over temperature.

- Temperature-Controlled Soldering Iron: These soldering irons feature adjustable temperature settings, allowing users to select the desired heat level for different soldering applications. They are versatile and can handle a wide range of soldering tasks.

- Cordless Soldering Iron: Cordless soldering irons provide the convenience of portability. They are battery-powered and are useful for soldering in locations where access to electrical outlets is limited.

- Soldering Stations: Soldering stations are comprehensive setups that include a soldering iron, temperature control unit, and other features like digital displays and advanced temperature regulation. They provide precise temperature control and are suitable for professional soldering applications.

Specialized Soldering Tools

In addition to soldering irons, several specialized soldering tools are designed to facilitate specific soldering tasks. These tools enhance precision, efficiency, and safety during soldering. Some common specialized soldering tools include:

- Desoldering Pump: A desoldering pump, also known as a solder sucker, is used to remove solder from joints or components. It creates a vacuum to suck up molten solder, allowing for easy removal.

- Hot Air Rework Station: Hot air rework stations combine a soldering iron with a hot air gun. They are used for tasks such as surface mount component removal, reflow soldering, and heat-shrink tubing.

- Soldering Tweezers: Soldering tweezers have fine, pointed tips that allow for precise handling of small components during soldering. They are particularly useful in surface mount soldering.

Soldering Aid Tools

Soldering aid tools assist in holding components, manipulating solder, and achieving clean soldering joints. These tools provide stability, prevent burns, and ensure accuracy during soldering. Some common soldering aid tools include:

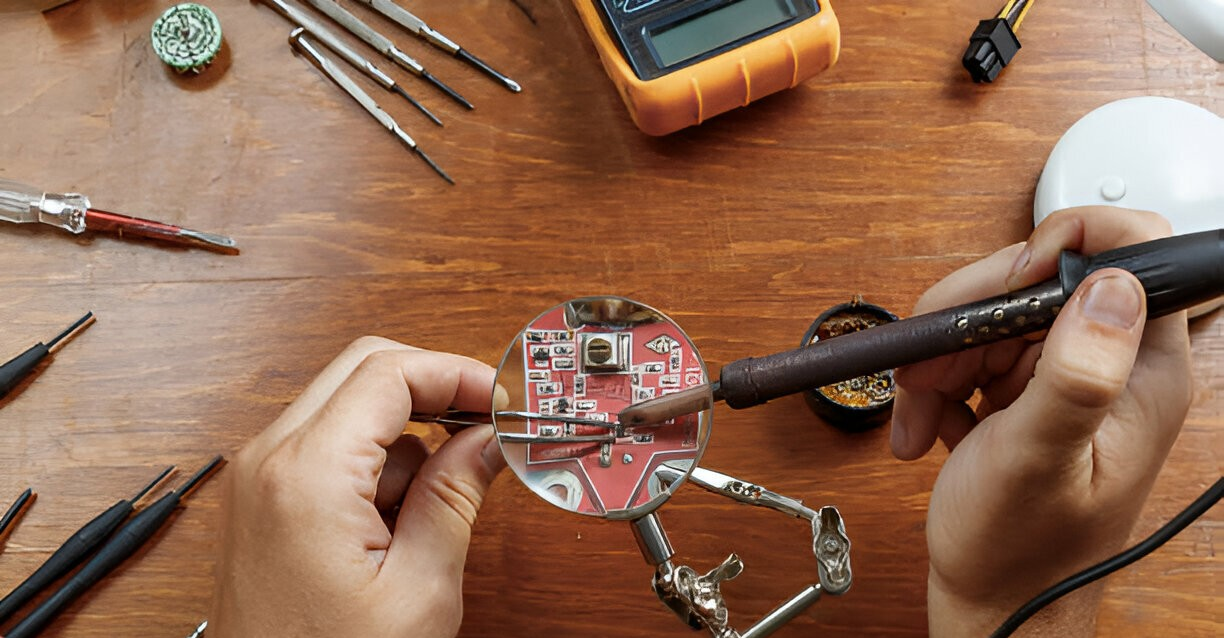

- Soldering Helping Hand: A soldering helping hand is a tool with adjustable clips and magnifying glass to hold the workpiece in place while soldering. It frees up your hands and provides stability during delicate soldering tasks.

- Soldering Third Hand: Similar to a helping hand, a soldering third hand is designed with multiple adjustable arms and clips to hold components or wires in place during soldering.

- Soldering Mat: A heat-resistant soldering mat provides a safe surface for soldering. It protects your work area from heat damage and prevents accidental solder spills.

Understanding the different types of soldering tool accessories is essential for efficient and successful soldering. By selecting the appropriate solder, soldering iron, and specialized tools, you can achieve clean and professional soldering joints. In the next section, we will explore how to effectively use these soldering tool accessories for optimal results.

How to Use Soldering Tool Accessories

Now that you have a good understanding of the various types of soldering tool accessories, it's time to learn how to use them effectively in your soldering projects. This section will provide step-by-step guidance on using different soldering tool accessories, from preparation to safety tips.

Preparation for Soldering

Before starting any soldering project, it's essential to prepare your workspace and gather the necessary materials. Follow these steps for proper preparation:

- Clean your work area: Ensure that your work surface is clean and free from any debris or flammable materials. This will help prevent accidents and ensure a safe soldering environment.

- Gather the required materials: Collect all the tools and materials required for your soldering project, including solder, soldering iron, soldering tool accessories, components, and any supporting materials like flux or soldering paste.

- Secure your workpiece: Use a soldering helping hand or third hand tool to hold your workpiece securely in place. This will provide stability and prevent any movement during soldering.

- Prepare your soldering iron: Check that your soldering iron is in good working condition and properly heated. Make sure the soldering iron tip is clean and tinned for optimal performance.

Using Soldering Irons and Solder

The soldering iron is the primary tool used in soldering, along with solder. Follow these steps for using soldering irons effectively:

- Heat up the soldering iron: Allow your soldering iron to heat up to the appropriate temperature for your solder and workpiece. The recommended temperature may vary depending on the type of solder and the materials being soldered.

- Tin the soldering iron tip: Apply a small amount of solder to the tip of the soldering iron. This process, known as tinning, helps improve heat transfer and ensures better solder flow.

- Apply flux (if necessary): If you're working with materials that require flux for better solder flow, apply a small amount of flux to the joint or workpiece.

- Heat the joint: Bring the heated soldering iron tip in contact with the joint or workpiece to transfer heat. The heat should be sufficient to melt the solder and create a strong bond.

- Apply solder: Once the joint is heated, touch the solder wire to the joint, allowing the solder to flow and coat the joint evenly. Avoid excessive solder, as it can lead to poor connections or solder bridges.

- Remove the soldering iron: After a few seconds, remove the soldering iron from the joint, but ensure that the joint remains undisturbed until the solder cools and solidifies.

Related Article: Soldering vs. Desoldering: Techniques and Best Practice

Safety Tips for Using Soldering Tools

Soldering involves working with high temperatures and potentially hazardous materials. Follow these safety tips to ensure a safe soldering experience:

- Work in a well-ventilated area: Soldering can release fumes, so it's crucial to work in a well-ventilated space or use a fume extractor to remove any harmful smoke or vapors.

- Wear appropriate safety gear: Wear safety glasses or goggles to protect your eyes from solder splatter or debris. Additionally, consider wearing heat-resistant gloves to protect your hands from accidental burns.

- Avoid touching the soldering iron tip: The soldering iron tip can reach high temperatures, so always handle it with caution. Use the designated stand to rest the soldering iron when not in use, and never touch the hot tip directly.

- Disconnect power when not in use: When taking breaks or finishing your soldering session, always disconnect the power supply to your soldering iron. This prevents accidental burns and reduces the risk of fire.

By following these guidelines, you can use soldering tool accessories effectively, ensuring clean and reliable soldering joints while maintaining a safe working environment. In the next section, we will discuss essential maintenance tips to prolong the lifespan of your soldering tools.

Maintenance of Soldering Tools

Proper maintenance of your soldering tools is essential to ensure their longevity and optimal performance. This section will provide you with valuable tips on cleaning, caring for, and storing your soldering tools to keep them in top condition.

Cleaning and Caring for Your Soldering Iron

- Regular tip cleaning: Clean the soldering iron tip after each use to remove any excess solder or debris. Use a damp sponge or brass tip cleaner to gently wipe the tip while it's still hot. Avoid using abrasive materials that can damage the tip.

- Remove oxidation: Over time, the soldering iron tip may develop oxidation, affecting its heat transfer. To remove oxidation, use a tip tinner or a specialized tip cleaner to restore the tip's performance.

- Avoid excessive heat: Exposing your soldering iron to excessive heat for prolonged periods can damage the tool. Follow the manufacturer's guidelines regarding temperature settings and avoid leaving the soldering iron running when not in use.

- Replace worn-out tips: Soldering iron tips can wear out over time, affecting their performance. Replace worn-out or damaged tips promptly to maintain optimal soldering results.

Proper Storage of Soldering Tools

- Allow cooling before storage: Before storing your soldering iron, ensure that it has completely cooled down. Attempting to store a hot soldering iron can lead to accidents or damage.

- Use a designated storage area: Designate a specific area or toolbox to store your soldering tools and accessories. Keep them organized and protected from dust, moisture, and potential damage.

- Store soldering iron with care: When storing your soldering iron, use a designated holder or stand to keep it upright and prevent accidental contact with flammable or delicate materials.

- Secure loose accessories: Ensure that any loose soldering tool accessories, such as solder wire or specialized tools, are properly stored and secured to prevent damage or loss.

How to Handle Soldering Accessories for Longevity

- Handle solder with care: Solder wire is delicate and can be easily damaged. Avoid bending or kinking the solder wire, as it can affect its flow and quality. Store solder wire in a cool, dry place to prevent oxidation.

- Clean soldering aid tools: Regularly clean soldering aid tools, such as helping hands or tweezers, to remove any solder residue or debris. This will help maintain their effectiveness and prolong their lifespan.

- Inspect cables and cords: Periodically inspect the cables and cords of your soldering tools for any signs of damage or wear. Replace any frayed or damaged cables to prevent electrical hazards.

- Follow manufacturer's instructions: Always refer to the manufacturer's instructions for specific maintenance guidelines for your soldering tools. Different tools may have unique requirements, so it's essential to follow the recommended practices.

By following these maintenance tips, you can extend the lifespan of your soldering tools and ensure consistent performance throughout your soldering projects. In the next section, we will delve into the process of selecting the right soldering tools for your specific projects.

Choosing the Right Soldering Tools for Your Project

Choosing the right soldering tools for your project is crucial to ensure efficient and successful soldering. In this section, we will discuss the factors to consider when selecting soldering tools and provide guidance on how to make informed decisions.

Understanding Your Project Needs

- Project type: Consider the nature of your project. Are you working on electronics, plumbing, jewelry making, or other specialized applications? Different projects may require specific soldering tools and accessories.

- Soldering complexity: Evaluate the complexity of your soldering tasks. Are you working with small components, surface mount technology, or larger joints? Complex projects may require more advanced soldering tools.

- Required precision: Determine the level of precision needed for your project. Some projects may require fine-tipped soldering irons and specialized tools for intricate work, while others may be more forgiving in terms of precision.

- Project scale: Consider the size and scale of your project. Larger projects may necessitate more powerful soldering irons or additional tools to ensure efficient and timely completion.

Determining the Right Soldering Tools

- Soldering iron wattage: The wattage of your soldering iron affects its heating capacity. Higher wattage irons deliver more heat, making them suitable for larger joints and faster soldering. Lower wattage irons are ideal for delicate work.

- Temperature control: Temperature-controlled soldering irons offer precise temperature management, allowing you to adjust the heat according to your project requirements. This feature is essential for projects that involve temperature-sensitive components or materials.

- Specialty soldering tools: Assess whether your project requires any specialized soldering tools such as hot air rework stations, desoldering pumps, or soldering tweezers. These tools cater to specific needs and can greatly enhance your soldering experience.

- Quality and reliability: Invest in high-quality soldering tools from reputable manufacturers. Quality tools offer better performance, durability, and safety. Read reviews, seek recommendations, and choose tools known for their reliability.

Where to Buy Soldering Tools and What to Look For

- Local electronics or hardware stores: Visit local stores that specialize in electronics or hardware to explore their selection of soldering tools. This allows you to see the tools in person, ask questions, and receive guidance from knowledgeable staff.

- Online retailers: Online platforms offer a wide range of soldering tools and accessories, often at competitive prices. Read product descriptions, customer reviews, and seller ratings to make informed purchasing decisions.

- Brand reputation: Consider reputable soldering tool brands known for their quality and reliability. Research and choose brands that have a history of manufacturing reliable and durable tools.

- Warranty and customer support: Check if the soldering tools come with a warranty or guarantee. Additionally, assess the availability of customer support should you encounter any issues or require assistance after purchase.

By considering your project needs, understanding the types of soldering tools available, and making informed purchasing decisions, you can select the right soldering tools that will meet your requirements and contribute to successful soldering outcomes.

Related Article: Choosing the Right Soldering Iron: A Buyer's Guide

Elevating Your Soldering Artistry

In wrapping up our exploration into the fascinating world of soldering and its essential tools and accessories, it's clear that mastering soldering goes beyond just having the right technique. The quality of your work and the ease with which you can complete projects are significantly enhanced by understanding and utilizing the appropriate soldering tool accessories. From choosing the right type of solder to selecting the best soldering iron for your needs, and not forgetting the importance of regular maintenance, each element plays a pivotal role in your soldering success.

Armed with this comprehensive guide, you're now equipped to make informed decisions about the tools that will best suit your projects, ensuring precision, durability, and quality in every joint you solder. Whether you're a beginner eager to start your soldering journey or a seasoned pro looking to refine your skills further, the world of soldering offers endless possibilities for creativity and innovation.