Bar Clamps: A Complete Guide for DIY Enthusiasts

Bar clamps are essential tools for woodworking, metalworking, and various DIY projects. They are designed to hold and secure materials, such as wood or metal, in place while you cut, drill, glue, or fasten them.

This complete guide will provide a comprehensive overview of bar clamps, their types, key features, how to choose the right one for your needs, usage and safety tips, maintenance and storage, and popular brands and models.

Table of Contents

- Types of Bar Clamps

- Key Features and Components

- How to Choose the Right Bar Clamp

- Proper Usage and Safety Tips

- Maintenance and Storage

- Popular Brands and Models

- Common Bar Clamps Problems

- Innovative Bar Clamp Accessories

- Affordable Alternatives to Popular Bar Clamps

- Clamping Hacks: Creative Uses for Bar Clamps in Your Workshop

- Conclusion

Types of Bar Clamps

- F-Clamps

F-clamps, also known as bar clamps or speed clamps, are versatile and easy to use. They feature a sliding jaw that can be adjusted quickly along the bar and tightened with a screw mechanism. F-clamps are ideal for woodworking, as they offer excellent clamping pressure and can accommodate different material thicknesses.

- Parallel Clamps

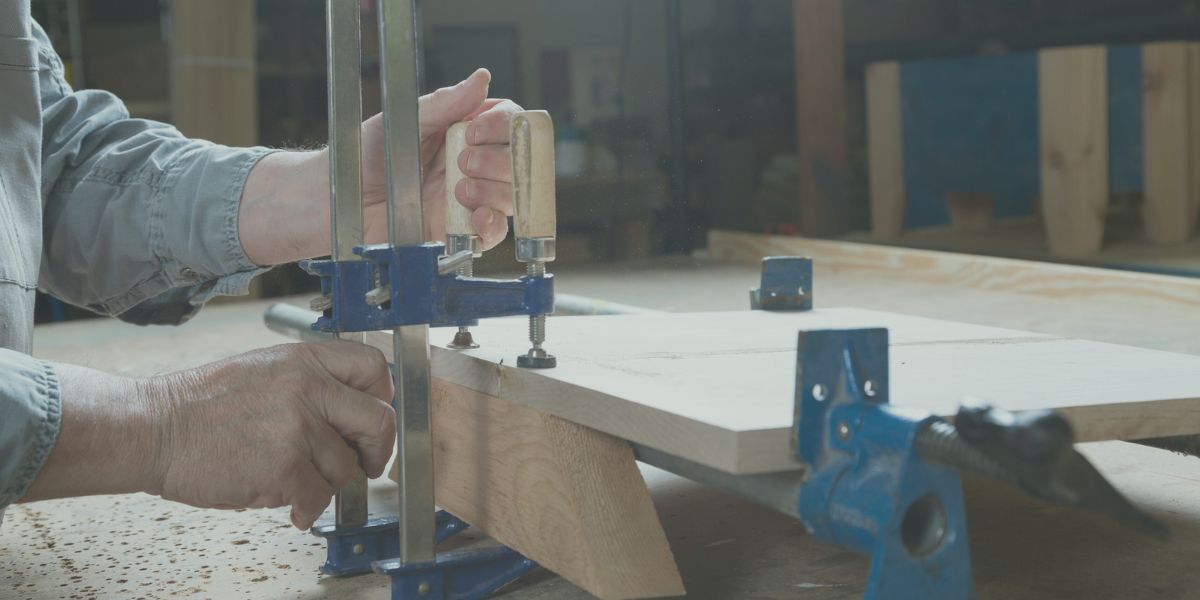

Parallel clamps are designed for precise and even pressure distribution, making them perfect for tasks requiring accurate alignment, such as gluing panels or cabinetry. They have jaws that remain parallel to each other during clamping, ensuring that the workpiece stays flat and square.

- Pipe Clamps

Pipe clamps are an affordable and customizable option for DIY enthusiasts. They consist of a clamp head and tail that attach to a length of pipe, allowing users to create clamps of various sizes based on their project requirements. These clamps are suitable for large-scale projects, such as building furniture.

- Quick-Grip Clamps

Quick-grip clamps, also known as one-handed bar clamps, are designed for fast and easy clamping with one hand. They have a trigger mechanism that allows users to adjust the clamp's pressure quickly and release it with ease. These clamps are ideal for light-duty tasks and quick fixes.

Related Article: What is a C-Clamp?

Key Features and Components

- Clamping Pressure

Clamping pressure is the amount of force exerted by the clamp on the workpiece. It is essential to choose a clamp with adequate clamping pressure for your project to ensure that the materials are held securely in place.

- Bar Length and Material

Bar length determines the maximum width of the material that can be clamped. Bars can be made from steel, aluminum, or other materials, each offering different levels of strength and durability. Choose a bar clamp with a suitable length and material based on your project's requirements.

- Jaws

The jaws of a bar clamp hold the workpiece in place. They can be made from various materials, such as plastic, wood, or metal, and may feature protective pads to prevent damage to the workpiece. Consider the size and material of the jaws when selecting a bar clamp.

- Throat Depth

Throat depth refers to the distance between the top of the jaw and the center of the clamp's screw. This measurement determines the maximum thickness of the material that can be clamped. Ensure that the throat depth of the clamp you choose is suitable for your project.

How to Choose the Right Bar Clamp

1. Determine the type of clamp needed based on your project requirements.

Different types of bar clamps are suited for various tasks. For example, F-clamps are versatile and perfect for woodworking projects that require strong clamping pressure, while parallel clamps are ideal for tasks that need precise alignment, such as gluing panels. Assess your project's needs and choose a clamp type accordingly.

2. Consider the clamping pressure required for secure and accurate clamping.

The clamping pressure varies among different types of bar clamps. For heavy-duty tasks or projects that involve dense materials, such as hardwood, it is essential to select a clamp with a high clamping pressure to hold the workpiece securely in place. For lighter tasks or delicate materials, a clamp with lower clamping pressure may be more suitable to avoid damaging the workpiece.

3. Evaluate the desired bar length and material to accommodate your workpiece.

The bar length determines the maximum width of the material that can be clamped. For example, if you are working on a project that requires clamping 36-inch wide panels, you should choose a bar clamp with at least a 36-inch bar. The material of the bar also plays a role in the clamp's strength and durability. Steel bars are typically stronger than aluminum bars, but they may be heavier and more susceptible to rust.

4. Assess the jaw size and material to prevent damage to your materials.

The jaws of a bar clamp hold the workpiece in place and can be made from various materials, such as plastic, wood, or metal. When selecting a bar clamp, consider the size of the jaws to ensure they can adequately grip your workpiece. Additionally, pay attention to the jaw material and whether it features protective pads. For delicate materials or surfaces, choose a clamp with non-marring pads to prevent damage.

5. Ensure that the throat depth is appropriate for the thickness of your workpiece.

The throat depth of a bar clamp refers to the distance between the top of the jaw and the center of the clamp's screw. This measurement determines the maximum thickness of the material that can be clamped. For instance, if you are working with 3-inch thick boards, you would need a clamp with a throat depth of at least 3 inches. Select a bar clamp with an appropriate throat depth based on the thickness of the materials you plan to work with.

Proper Usage and Safety Tips

- Always wear safety gear, such as goggles and gloves, when working with bar clamps.

- Ensure that the clamp is properly adjusted to fit the workpiece securely without over-tightening.

- Use the appropriate number of clamps for the size and weight of your materials.

- Inspect the clamp for any signs of wear or damage before use.

- Follow the manufacturer's instructions for proper usage and care.

Related Article: What You Need To Know About Spring Clamps

Maintenance and Storage

- Keep your bar clamps clean and free of debris by wiping them down after each use.

- Lubricate the screw and sliding mechanisms regularly to ensure smooth operation.

- Store your clamps in a dry and cool location to prevent rust and corrosion.

- Organize and hang your clamps on a clamp rack or pegboard for easy access and space-saving storage.

Popular Brands and Models

- Bessey: Known for their high-quality and reliable clamps, Bessey offers a wide range of bar clamps, including F-clamps, parallel clamps, and pipe clamps.

- Jorgensen: Jorgensen is a trusted brand for woodworking tools, offering durable and sturdy bar clamps, such as their Cabinet Master parallel clamps and Pony pipe clamps.

- Irwin: Irwin's Quick-Grip clamps are popular among DIY enthusiasts for their ease of use and versatility in various projects.

- DeWalt: DeWalt offers a range of heavy-duty bar clamps designed for professional use, such as their Medium and Large Trigger Clamps.

Common Bar Clamp Problems

Bar clamps are indispensable tools in woodworking and carpentry, providing the necessary pressure to glue up pieces securely or hold components steady during assembly or cutting. However, even the most robust tools can encounter issues, and understanding these common problems can help professionals maintain their equipment and ensure projects proceed smoothly.

Misalignment

- Cause and Effect: One frequent issue with bar clamps is misalignment, where the clamp's jaws do not meet perfectly perpendicular to the workpiece. This can lead to uneven pressure distribution, potentially causing the pieces being glued to shift out of alignment.

- Preventive Measures: Regularly inspect the alignment of your clamps and consider using alignment tools or jigs specifically designed for checking and adjusting clamp jaws. Ensuring your work surface is level can also help prevent misalignment caused by an uneven base.

Slipping

- The Problem: Slipping is another common issue, where the clamp's grip on the workpiece isn't secure, causing it to slide or move during the gluing or assembly process. This can compromise the integrity of the joint or result in an uneven application of pressure.

- Solutions: To counteract slipping, make sure the clamp faces are clean and free of any debris or lubricant that could reduce friction. Using clamps with serrated or textured jaws can also improve grip. Additionally, applying a small piece of non-slip shelf liner or similar material between the clamp faces and the workpiece can enhance grip without damaging the wood.

Corrosion and Wear

- Long-Term Concerns: Over time, bar clamps, especially those made from metal, are susceptible to corrosion and wear. This not only affects their appearance but can also impair their functionality, making them harder to adjust or reducing their clamping force.

- Maintenance Tips: Regular maintenance is key to preventing corrosion and wear. Store clamps in a dry, controlled environment to minimize exposure to moisture. Applying a thin layer of machine oil to the bar and moving parts can protect against rust and ensure smooth operation. Inspect your clamps periodically for signs of wear and replace any components that are damaged or excessively worn.

Understanding these common problems with bar clamps is the first step towards mitigating them. By taking preventive measures and performing regular maintenance, professionals can extend the life of their clamps and maintain the high standard of their work.

Innovative Bar Clamp Accessories

Bar clamps are fundamental tools in any woodworking shop, but their functionality can be significantly enhanced with the right accessories. These innovative additions not only increase the versatility of bar clamps but also improve efficiency and precision in various woodworking projects. Understanding and utilizing these accessories can elevate your work and solve common clamping challenges.

Protective Pads

- Purpose and Benefits: Protective pads are designed to be affixed to the clamp's jaws to prevent damage to the workpiece. They distribute clamping pressure more evenly and prevent imprints or marring on softer woods.

- Application: These pads are typically made from soft, durable materials like silicone or rubber. They can be easily attached and removed, making them a versatile addition to any clamp. For woodworkers concerned about finish and aesthetics, these pads are indispensable.

Extension Bars

- Expanding Capacity: Extension bars can be attached to the existing bar of the clamp, effectively extending its length and increasing its capacity. This is particularly useful for larger projects where standard clamp sizes are insufficient.

- Usage Tips: When using extension bars, it's essential to ensure they are securely fastened to prevent slippage or misalignment. Additionally, be mindful of the increased leverage and ensure the clamp is adequately supported.

Clamp Edge Guides

- Guided Precision: Clamp edge guides transform a standard bar clamp into a precision cutting guide. By attaching a straight edge to the clamp, users can guide circular saws, routers, or jigsaws along the length of the workpiece for straight, accurate cuts.

- Implementation: Look for edge guides that are easy to adjust and lock into place for maximum versatility. They should be made from durable materials to withstand the wear and tear of power tools.

Integrating these innovative accessories into your woodworking toolkit can significantly enhance the functionality and versatility of your bar clamps. Whether you're looking to protect delicate workpieces, extend your clamp's reach, or achieve precise cuts, there's likely an accessory designed to meet your needs. As the industry continues to innovate, staying informed about new accessories can keep you ahead of the curve and improve the quality and efficiency of your work.

Clamp Up Your Budget: Affordable Alternatives to Popular Bar Clamps

In the world of woodworking, having the right tools can make all the difference. However, for hobbyists or professionals on a tight budget, the cost of high-quality bar clamps can be prohibitive. Fortunately, the market offers several affordable alternatives that do not compromise significantly on performance or durability. Exploring these options can help woodworkers maintain their craft's quality without breaking the bank.

Quick-Release Clamps

- Why Consider: Quick-release clamps offer a convenient and time-saving alternative to traditional bar clamps. While they may not always match the heavy-duty clamping force of more expensive models, they are suitable for a wide range of projects and are particularly user-friendly.

- Budget Tip: Look for generic or lesser-known brands that offer quick-release functionality. These often come at a fraction of the price of big-name brands but still provide reliable performance for most tasks.

Pipe Clamps

- Cost-Effective Versatility: Pipe clamps are an excellent option for woodworkers looking to maximize their budget. Using standard threaded pipes, these clamps can be easily customized to various lengths, offering versatility that is hard to beat.

- Savings Strategy: Purchase the clamp fixtures separately and then source the pipes locally. This approach allows you to create a set of clamps at different lengths without investing in multiple expensive bar clamps.

DIY Bar Clamps

- Personalized Tools: For the truly budget-minded or those with a knack for DIY, making your own bar clamps is a rewarding project. With some basic materials and tools, custom bar clamps can be tailored to specific needs and preferences.

- Getting Started: There are numerous online tutorials and plans available that guide you through the process of creating your own clamps. Materials like scrap metal bars, threaded rods, and wooden blocks can be transformed into effective clamping tools.

By exploring these affordable alternatives, woodworkers can equip themselves with a variety of clamping options that cater to different needs and projects. This approach not only saves money but also encourages creativity and resourcefulness in the workshop.

Clamping Hacks: Creative Uses for Bar Clamps in Your Workshop

Bar clamps are indispensable tools in woodworking, offering precision and strength in holding pieces together. However, their utility extends far beyond the confines of traditional woodworking projects. Exploring creative uses for bar clamps can reveal their versatility and potential to solve a variety of everyday challenges or enhance other hobbies. This adaptability not only showcases the ingenuity of users but also adds value to this seemingly straightforward tool.

Photography and Videography

- Stabilizing Equipment: Bar clamps can be used to secure cameras, lights, or microphones to various surfaces, providing stability and flexibility in shooting setups. This is particularly useful in tight spaces or when conventional stands are not available.

- DIY Rigging: Creative rigging solutions using bar clamps can help achieve unique angles and perspectives without investing in expensive specialized equipment.

Home Organization

- Temporary Shelves: By clamping boards to walls or sturdy furniture, you can create temporary shelves or workspaces. This is ideal for situations where permanent fixtures are not possible or desirable, like in rental properties or temporary setups.

- Cable Management: Larger clamps can organize and secure cables along desks or entertainment centers, helping to maintain a cleaner and more organized space.

Fitness

- Resistance Band Anchor: Securely clamp resistance bands to a fixed point for a variety of exercises. This makeshift setup is perfect for home gyms where space and equipment might be limited.

- Yoga Prop: Use a clamp to hold a yoga mat rolled up for storage or transportation. Alternatively, a softly padded clamp can serve as a prop to assist in certain yoga poses or stretches.

Arts and Crafts

- Frame Assembly: Clamps are invaluable for holding frames securely while the glue dries. They ensure corners are tight and the frame is square.

- Fabric Stretching: For painting or silk-screening, use clamps to stretch fabric over a frame, ensuring a smooth, even surface for your work.

Exploring these unconventional uses for bar clamps not only highlights their versatility but also encourages a mindset of innovation and resourcefulness. Whether in the workshop, home, studio, or beyond, the potential applications of bar clamps are limited only by one's imagination. By thinking outside the box, individuals can leverage these tools in numerous aspects of their daily lives, underscoring the value of creativity in practical problem-solving.

Conclusion

Bar clamps are an indispensable tool for DIY enthusiasts, providing secure and accurate clamping for various projects. By understanding the different types of bar clamps, their key features, and how to choose the right one for your needs, you can ensure successful and efficient completion of your projects.

Additionally, proper usage, maintenance, and storage of your clamps will prolong their lifespan and guarantee their reliability. With the right bar clamp in hand, you can tackle any DIY project with confidence and precision.